When heat transfer leaks you can risk contamination in your whole system. There are typically four main reasons a leak could occur: water hammering, stress corrosion cracking, over pressurizing, and lack of supports.

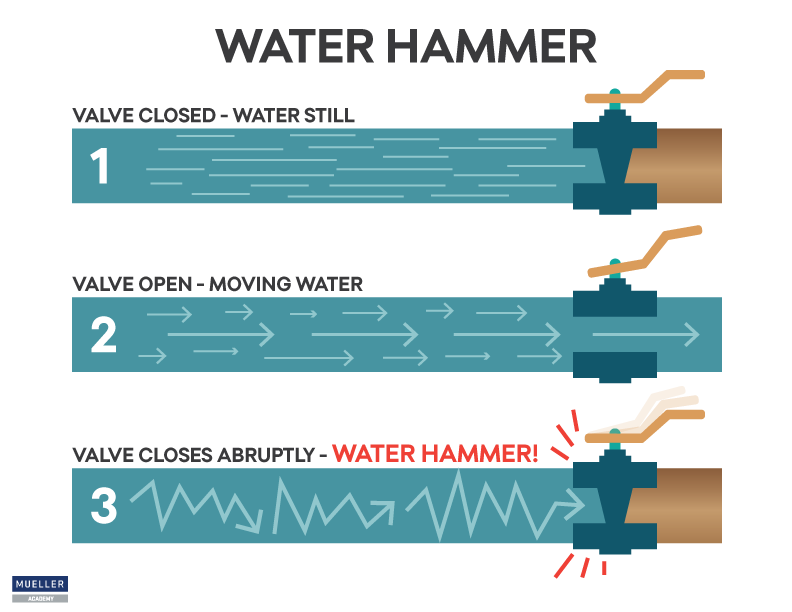

Water Hammering

Imagine a bouncy ball in a pipe stuck between two valves bouncing back and forth, this is very similar to water hammering (or steam hammering). When a valve is closed too quickly, the contents of the pipe will slam into the valve causing a 180° energy change. This happens over and over creating vibrations that travel through the pipes; these vibrations may cause cracking.

Stress Corrosion Cracking

If the media traveling through the pipes is not treated correctly, chlorides will enter the system causing stress corrosion cracking. The build up of corrosion products and stress can cause cracking and fatigue in the material of the system. To lower the likelihood of stress corrosion cracking, the heat exchanger should not have crevices where media can become stagnant allowing materials to accumulate.

Over Pressurizing

A heat transfer unit is designed for a maximum pressure. When that maximum is exceeded holes and cracks will begin to form allowing media to leak from the unit.

Lack of Supports

When the heat transfer unit’s connections are not properly supported, they are unable to withstand the usual wear and tear imposed on the system. Think about vehicles driving across a bridge, year after year pressure is applied to the bridge supports causing normal wear and tear on the structure. However, if the bridge is not properly braced, then the supports will become stressed. The bridge will not be able to support the load traveling across which and may fail. This is similar to a heat transfer unit, but instead of vehicles traveling across a bridge, there is media flowing through the system.

Heat transfer leaks should not be taken lightly since the product within your system can become contaminated no matter what caused the leak. Regular maintenance is always the best prevention. If your plate heat exchanger is not performing the way you expect, contact our service and repair experts at Paul Mueller Company.

Leaking can occur for several reasons. Preventative maintenance is the best way to avoid leaks and damage to your plate heat exchanger. Check out this efficiency guide for some helpful tips and diagrams on keeping your PHE in optimal running condition and avoid contaminating your product.