"Expand your brewery" - it's such a vague term. What kind of expansion? You can expand your actual space. You can expand your brewing capacity. Heck, you could be expanding to distribution outside your brewhouse for the first time!

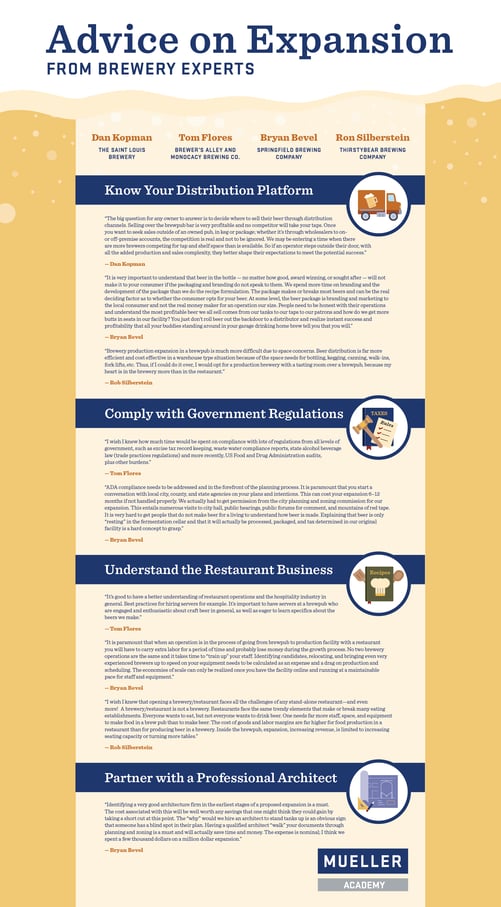

This infographic tackles all the elements of expansion in a topline way by using the “20/20 Hindsight” of brewery experts. These brewery leaders are offering up their most noteworthy hurdles with aspiring brewery owners. The information shared is a frank discussion about, “What they wish they had known.” We invite you to learn O.P.E. Style (Other People’s Experience).

Our Experts

Dan Kopman - The Saint Louis Brewery

Tom Flores - Brewer's Alley and Monocacy Brewing Co.

Bryan Bevel - Springfield Brewing Company

Ron Silberstein - Thirstybear Brewing Company

Know Your Distribution Platform

“The big question for any owner to answer is to decide where to sell their beer through distribution

channels. Selling over the brewpub bar is very profitable and no competitor will take your taps. Once

you want to seek sales outside of an owned pub, in keg or package; whether it’s through wholesalers to on-premise or off-premise accounts, the competition is real and not to be ignored. We may be entering a time when there are more brewers competing for tap and shelf space than is available. So if an operator steps outside their door, with all the added production and sales complexity, they better shape their expectations to meet the potential success.” — Dan Kopman

“It is very important to understand that beer in the bottle — no matter how good, award winning, or sought after — will not make it to your consumer if the packaging and branding do not speak to them. We spend more time on branding and the development of the package than we do the recipe formulation. The package makes or breaks most beers and can be the real deciding factor as to whether the consumer opts for your beer. At some level, the beer package is branding and marketing to the local consumer and not the real money maker for an operation our size. People need to be honest with their operations and understand the most profitable beer we all sell comes from our tanks to our taps to our patrons and how do we get more butts in seats in our facility? You just don’t roll beer out the backdoor to a distributor and realize instant success and profitability that all your buddies standing around in your garage drinking home brew tell you that you will.” — Bryan Bevel

“Brewery production expansion in a brewpub is much more difficult due to space concerns. Beer distribution is far more efficient and cost effective in a warehouse type situation because of the space needs for bottling, kegging, canning, walk-ins, fork lifts, etc. Thus, if I could do it over, I would opt for a production brewery with a tasting room over a brewpub, because my heart is in the brewery more than in the restaurant.” — Rob Silberstein

Comply with Government Regulations

“I wish I knew how much time would be spent on compliance with lots of regulations from all levels of government, such as excise tax record keeping, waste water compliance reports, state alcohol beverage law (trade practices regulations) and more recently, US Food and Drug Administration audits, plus other burdens.”— Tom Flores

“ADA compliance needs to be addressed and in the forefront of the planning process. It is paramount that you start a conversation with local city, county, and state agencies on your plans and intentions. This can cost your expansion 6–12 months if not handled properly. We actually had to get permission from the city planning and zoning commission for our expansion. This entails numerous visits to city hall, public hearings, public forums for comment, and mountains of red tape. It is very hard to get people that do not make beer for a living to understand how beer is made. Explaining that beer is only “resting” in the fermentation cellar and that it will actually be processed, packaged, and tax determined in our original facility is a hard concept to grasp.” — Bryan Bevel

Understand the Restaurant Business

“It’s good to have a better understanding of restaurant operations and the hospitality industry in general. Best practices for hiring servers for example. It’s important to have servers at a brewpub who are engaged and enthusiastic about craft beer in general, as well as eager to learn specifics about the beers we make.” — Tom Flores

“It is paramount that when an operation is in the process of going from brewpub to production facility with a restaurant you will have to carry extra labor for a period of time and probably lose money during the growth process. No two brewery operations are the same and it takes time to “train up” your staff. Identifying candidates, relocating, and bringing even very experienced brewers up to speed on your equipment needs to be calculated as an expense and a drag on production and scheduling. The economies of scale can only be realized once you have the facility online and running at a maintainable pace for staff and equipment.” — Bryan Bevel

“I wish I knew that opening a brewery/restaurant faces all the challenges of any stand-alone restaurant—and even

more! A brewery/restaurant is not a brewery. Restaurants face the same trendy elements that make or break many eating establishments. Everyone wants to eat, but not everyone wants to drink beer. One needs far more staff, space, and equipment to make food in a brew pub than to make beer. The cost of goods and labor margins are far higher for food production in a restaurant than for producing beer in a brewery. Inside the brewpub, expansion, increasing revenue, is limited to increasing seating capacity or turning more tables.” — Rob Silberstein

Partner with a Professional Architect

“Identifying a very good architecture firm in the earliest stages of a proposed expansion is a must.

The cost associated with this will be well worth any savings that one might think they could gain by taking a short cut at this point. The “why” would we hire an architect to stand tanks up is an obvious sign that someone has a blind spot in their plan. Having a qualified architect “walk” your documents through planning and zoning is a must and will actually save time and money. The expense is nominal; I think we spent a few thousand dollars on a million dollar expansion.” — Bryan Bevel

Additional Resources:

Expanding your brewery, whether it is physical space or capacity, there are several things to take into consideration. Mad Mole, a start up brewery in Wilmington, NC incorporated Serving Beer Tanks to help with cost/time and space savings. Check out their stories!